When it comes to maintaining beaches, few machines face a tougher job. Saltwater, sand, sun, and constant motion create some of the most extreme conditions for equipment. It’s no surprise that many beach cleaning machines struggle to stay reliable season after season.

But after 60 years of observing what works — and what doesn’t — one principle consistently stands out to us at Barber: simplicity beats complexity. Machines designed to be purely mechanical, with fewer moving parts and corrosion-resistant construction, consistently outperform those packed with electronics and vibration-heavy systems.

[01:00:02:17 – 01:00:06:01]

For a beach cleaner that is going to be in a saltwater environment,

[01:00:06:16 – 01:00:10:01]

the more electronics you put on it, the more problems you’re gonna have.

[01:00:10:09 – 01:00:11:17]

That’s been my experience

[01:00:14:03 – 01:00:18:20]

One of the major advantages of the Surf Rake is actually the simplicity.

[01:00:20:11 – 01:00:26:15]

I think sometimes people think that, you know, in this day and age, they need the latest and greatest more bells and whistles, electronics.

[01:00:27:15 – 01:00:29:18]

There are no electronics on the Surf Rake.

[01:00:29:20 – 01:00:32:02]

It’s a completely mechanical unit.

[01:00:32:21 – 01:00:39:02]

Also, the fewer moving parts, the less vibration that you have in the equipment, the longer it’s gonna last.

[01:00:41:21 – 01:00:46:00]

Every one of the other beach cleaners that’s out there is a sifting style piece of equipment.

[01:00:46:00 – 01:00:48:12]

With sifters, you must add vibration.

[01:00:48:12 – 01:00:50:23]

You must literally shake the machine

[01:00:50:23 – 01:00:57:14]

to get the sand to sift through. Adding sand, shaking through a machine, you’re gonna run into problems.

If you’re evaluating a beach cleaner for your municipality, resort, or private shoreline, understanding these design principles can help you avoid downtime, reduce maintenance costs, and extend the life of your investment.

Table of Contents

Why Electronics and Saltwater Don’t Mix

Electronics are everywhere in modern machinery, from vehicles to lawn equipment. But in a saltwater environment, every circuit board, sensor, or screen becomes a liability.

✔ Corrosion risk: Saltwater and moisture are highly conductive and corrosive, often leading to short circuits.

✔ Downtime: A failed electronic control module can sideline a machine, even if the rest of the unit is sound.

✔Repair costs: Specialized electronic parts are expensive and may require factory service.

For a piece of equipment that needs to run reliably day after day, less reliance on electronics often translates directly into more uptime.

For a piece of equipment that needs to run reliably day after day, less reliance on electronics often translates directly into more uptime.

The Value of Mechanical Simplicity

Mechanical systems offer two huge advantages for beach cleaning, as opposed to machines that have electronics on them:

- Ease of maintenance – Mechanical parts can often be serviced on-site with basic tools.

- Proven reliability – Fewer things can go wrong, and when they do, the fix is usually straightforward.

This is why many operators prefer mechanical beach cleaning machines. The Surf Rake, for example, is one of the only models that operates without electronics at all — a choice driven by decades of experience in coastal environments.

Fewer Moving Parts = Less Vibration

Another underappreciated factor in equipment longevity is vibration. Machines that rely on sifting sand through screens must use vibration to shake debris free. While effective in the short term, this constant shaking puts stress on bearings, joints, and frames.

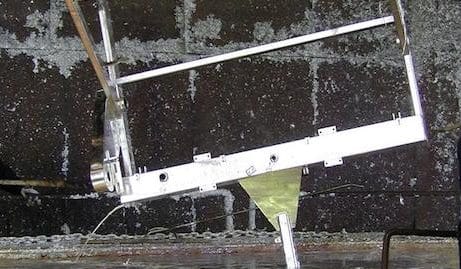

Beyond Simplicity: The Role of Hot-Dip Galvanizing

Simplicity isn’t the only ingredient in durability. Materials matter too. One major factor in extending a machine’s life is hot-dip galvanizing, a process where steel components are coated with a protective layer of zinc.

- Corrosion resistance: Hot-dip galvanizing provides a barrier against rust, which is especially critical in coastal salt air.

- Low maintenance: Unlike paint, which can chip and wear away, galvanized coatings bond to the metal and protect for decades.

- Cost efficiency: Investing in corrosion-resistant materials reduces replacement and repair costs over the lifetime of the machine.

For beach cleaning machines, where every component is exposed to abrasive sand and corrosive saltwater, galvanizing can mean the difference between a machine that lasts five years and one that lasts twenty.

You can learn more about hot dip galvanizing in our post on how hot dip galvanizing works to protect beach cleaners against rust.

Putting It All Together

The principles of long-lasting beach cleaning equipment are clear:

✔ Minimize electronics to avoid saltwater corrosion.

✔ Keep it mechanical for ease of maintenance and field reliability.

✔ Design with fewer moving parts to reduce vibration and wear.

✔ Use hot-dip galvanizing for maximum corrosion protection.

Conclusion

Beach maintenance teams have enough challenges without dealing with constant equipment breakdowns. By choosing machines designed with simplicity, mechanical reliability, and robust materials, you set yourself up for long-term success.

Whether you’re responsible for a busy resort, a municipal shoreline, or a private community beach, these principles will help you evaluate equipment that’s built not just to work, but to last.

Next Steps

✔ Learn more about how the Surf Rake employs these design concepts: How the Surf Rake Works

✔ Looking for help evaluating what beach cleaner is right for your beach?: Contact Our Team Now

frequently asked questions:

Longevity often comes down to design simplicity. Machines that rely on electronics, sensors, or vibration systems tend to fail sooner in harsh saltwater environments. Purely mechanical machines, like the Surf Rake, avoid those weak points — leading to longer lifespans and fewer costly repairs.

Yes. You can get the same or better results, while also being more reliable. Mechanical systems handle wet or compacted sand without clogging or shorting out, while still removing fine debris effectively. The key advantage is uptime: when electronics fail, the whole machine stops; mechanical components can usually be repaired in the field.

Hot-dip galvanizing coats steel components with zinc to prevent corrosion. In a coastal environment, this protection can mean the difference between five years of service and twenty. It’s one of the most effective ways to make beach cleaning machines last longer with less maintenance. It should also be noted that hot dip galvanizing is different than when manufacturers mention they ‘galvanize’ their equipment. This often refers to applied a coat on the surface of the steel, whereas hot dip galvanizing submerges the entire frame, so the inside and outsides are protected from rust.

Explore our deep-dive article on hot galvanizing here.

The only trade-off is fewer “bells and whistles.” Some electronic machines add dashboards or automatic sensors, but in saltwater conditions, these often create more problems than they solve. A mechanical setup focuses on what matters most — consistent, dependable performance day after day and operation that is easier to learn, execute, and sustain over time.