surf rake options

prevent corrosion with hot dip galvanizing

Hot dip galvanizing is a process that drastically increases the longevity of your machine by preventing rust from forming, despite the harsh beach conditions the SURF RAKE operates in. With guaranteed 15 year corrosion resistance, it offers the lowest long-term costs and maintenance.

how does hot dip galvanizing work?

Following extensive preparation, the entire steel frame of the machine is

immersed in molten zinc creating a tough protective coating, which is

metallurgically bonded to the steel.

Preparatory holes are drilled into the frame allowing the molten zinc to flow inside the steel frame to coat and protect the frame both inside and out.Following galvanization the frame receives a high quality industrial paint for a final layer of protection.

science & benefits of hot dip galvanizing

not all 'galvanizing' is created equal

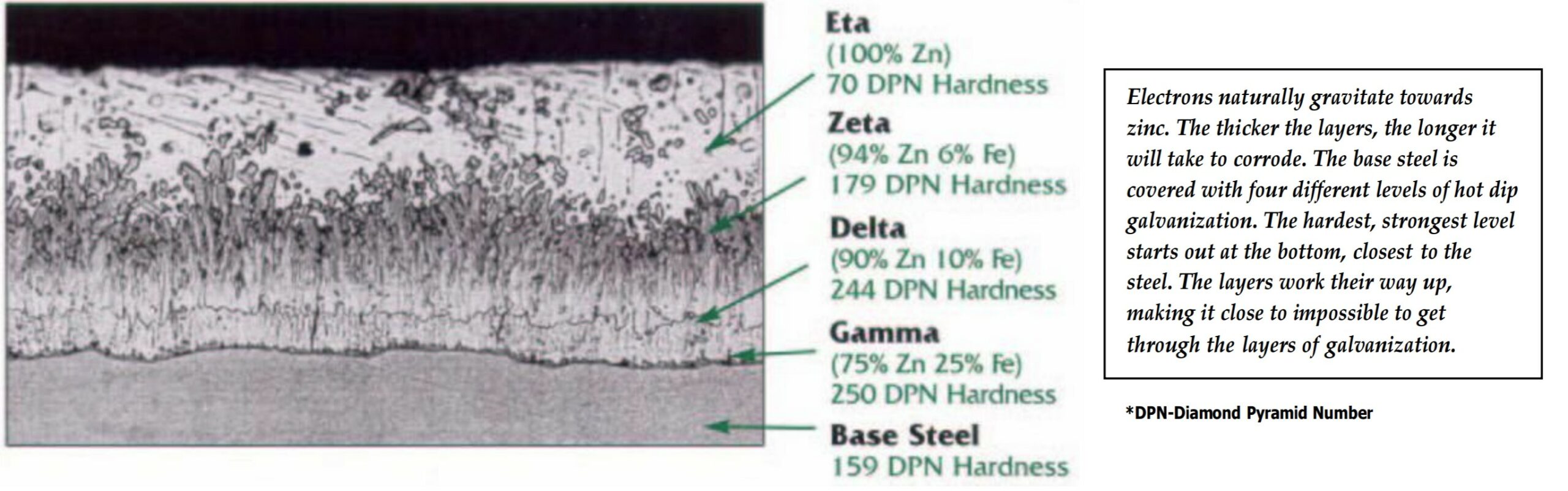

At 800 degrees Fahrenheit, molten zinc metallurgically bonds to the base steel. The layers that are formed with the steel (called iron zinc alloys) are actually harder than the base steel itself! The base steel and the molten zinc must be at a minimum of 800 degrees Fahrenheit, or this bond cannot occur. Many manufacturers claim ‘galvanizing,’ which is a cheaper process of applying a plate of galvanizing on top of steel, but the two are not chemically bonded in the same manner and do not offer the same level of corrosion protection.

importance of the dip

All components of the SURF RAKE are completely dipped into molten zinc. Because of this complete immersion, all surfaces, inside and out, are covered with a consistent layer of zinc. All steel surfaces, whether you can see them or not, are covered. Every crack, corner, crevice, and even the edges have the same thick layer of zinc bonded to their surface. Most other companies choose to spray paint a primer layer with zinc over their machines leaving room for application error. When hand spraying, small cracks and corners are easy to miss. This cold galvanizing only covers easily accessed areas and does not form a metallurgic bond with the base steel.

cathodic protection

Zinc will preferentially corrode and protect the base steel against rusting even when the coating is damaged. Other coverings which do not form the metallurgical bond will not be

able to protect the steel as well as hot dip galvanizing does. Hot dip galvanizing ensures that there is a thick layer, from four to six millimeters of zinc covering all surfaces.

save money

Machines will have a substantially longer life if they are hot dip galvanized. Sand, sea water and salt air all accelerate the deterioration of a beach cleaner. Your machine will always look great. You will save money on maintenance, no touching up rust spots, repainting, or replacing of corroded parts. Maintenance costs will go down and the overall machine life will increase.

Some of our competitors use a cheap inorganic zinc-rich paint which doesn’t come close to the quality of hot dip galvanization.

15-year guarantee

We are so confident in our hot dip galvanized frames that we guarantee the entire frame against failure due to rust for 15 years!

-Hot dip galvanizing your machine is the way to go! It offers the best protection available and guarantees a longer lasting frame. Barber machines are made to last!