SURF RAKE beach cleaners are operated by one person from the seat of a towing tractor. They provide safe, fast, and efficient beach cleaning.

The beach cleaner’s moldboard levels uneven areas in the sand to ensure an even surface for cleaning and controls the cleaning depth. It also guides the machine over large submerged objects, which protects the conveyor system and promises low-maintenance operation for the duration of the beach cleaner’s life.

Offset, individually replaceable stainless steel tines mounted on a belt-covered bar flight conveyor then rake debris from the sand toward the adjustable moldboard deflector plate, removing surface and submerged debris with ease.

Refuse bounces off the beach cleaner’s deflector moldboard and is deposited on the elevating portion of the conveyor , which transports the refuse to the hopper, while residual sand falls through the perforations in the conveyor.

Finally, the hopper/bucket of the beach cleaner can be hydraulically raised and tripped to dispose of its contents into a truck or container up to 9 feet high.

A number of proprietary features make the SURF RAKE the most effective and reliable beach cleaner on the market. We’ve been refining the SURF RAKE since 1966, so that each component is optimized for the long haul. Read more about them below.

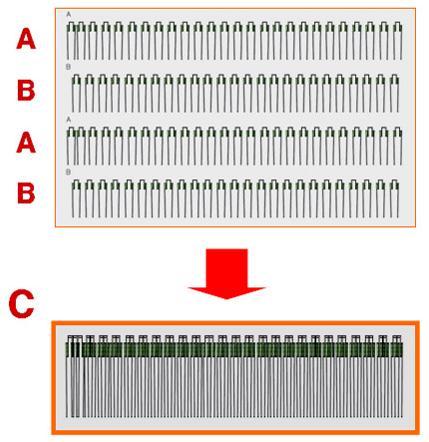

The S-belt is a perforated NRB Rubber belt with nylon layers that is practically wear-resistant and contains rows of mounted stainless steel tines. When the tines capture debris onto the beach cleaner’s conveyor, the perforations allow residual sand to fall back onto the beach, allowing the beach cleaner to only remove debris.

This improves performance and longevity in that it maximizes tine penetration and removal of extremely fine debris like cigarette butts, and it reduces the risk of residual sand removal & number of dump cycles and bulk waste removal cost. The conveyor is also easier to clean and clear of debris.

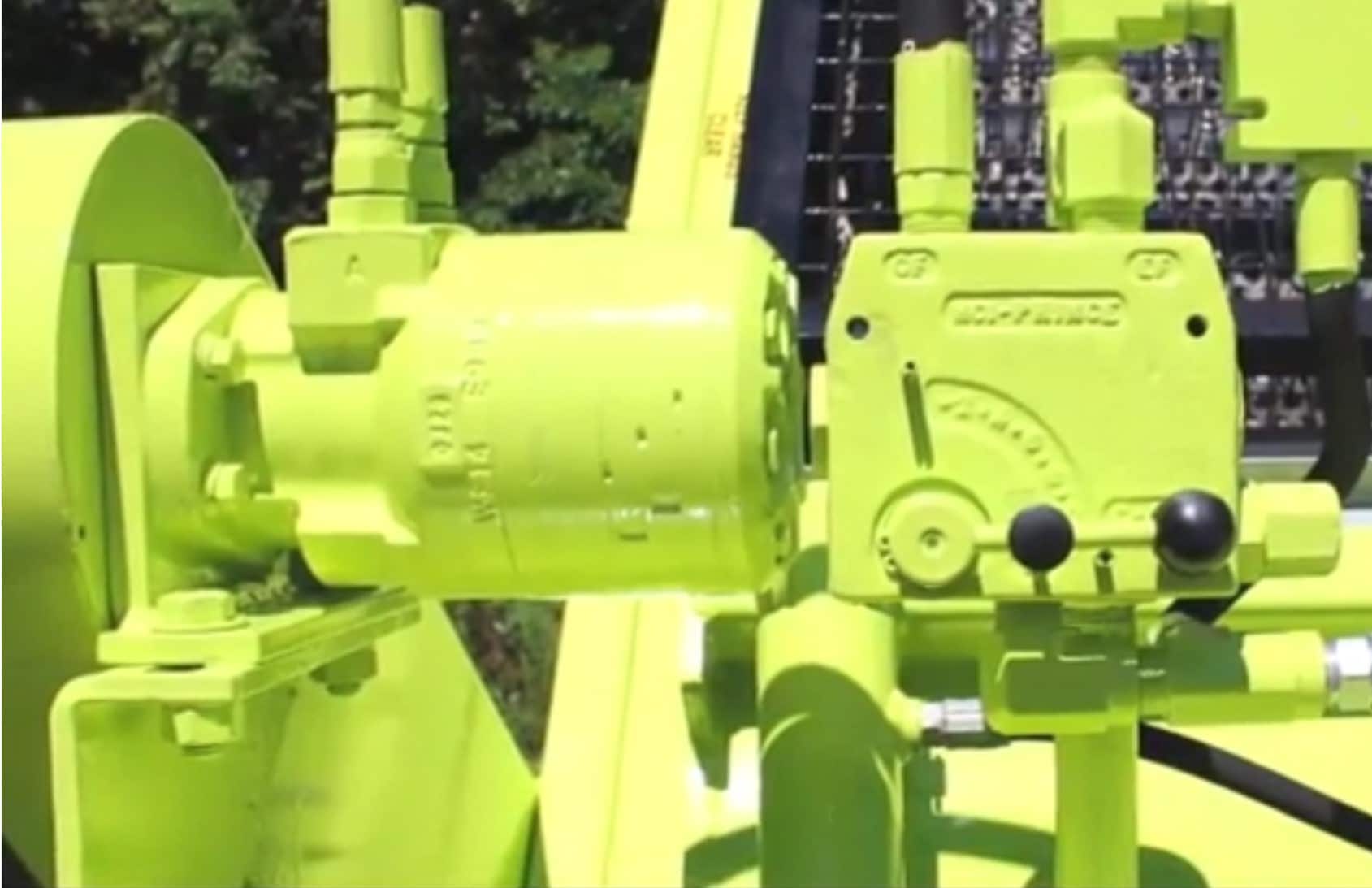

The SURF RAKE beach cleaner line features a hydraulic drive for smooth operation with major advantages . First, it provides excellent maneuverability. Power is transferred through a flexible hose, allowing the beach cleaner to clean while turning in the tightest of areas. Second, the beach cleaner’s flow control permits fine adjustments of the conveyor belt speed, independent of the tractor. Third, the hydraulic drive maintains the operator’s safety by eliminating exposed turning shafts. Fourth, the adjustable over-flow engages and resets automatically to protect our beach cleaners from oversized objects.

Hundreds of double-torsion, three-coil stainless steel tines are mounted in offset rows rake through the sand every second, removing the unwanted debris. Accordingly, our beach cleaner machines are capable of capturing even the smallest objects from the sand such as glass, cigarette butts and pop-tops and depositing them in the hopper, leaving the sand cleaner, safer and more inviting.

The tines offer greater durability and improved resistance to corrosion in saltwater environments. Quality, durable and corrosion resistant components are important to any beach cleaner’s operation. Tines are individually replaceable on each beach cleaner for simplified maintenance.

Now that you know the basics of how the SURF RAKE works, learn about its available options to customize it to your specific application.

Home / Beach Cleaning Machines / Surf Rake / How It Works

Copyright H Barber & Sons Inc. 2025