When you’re evaluating a beach cleaning machine, the purchase price is only one part of the equation.

The real question is: will it reliably deliver clean, safe beaches within the time and conditions you’re working with?

[01:00:04:07 – 01:00:08:03]

There are three primary considerations when someone is purchasing a beach cleaner.

[01:00:08:03 – 01:00:09:07]

The first one

[01:00:09:07 – 01:00:13:07]

efficiency. Can you get out there on the beach, make the beach clean,

[01:00:13:07 – 01:00:16:04]

make it a beautiful safe environment for your patrons?

[01:00:17:19 – 01:00:21:05]

The second factor is always how fast can you get it done.

[01:00:22:02 – 01:00:26:16]

beach like this that I’m standing in front of, they will have to be off the beach by eight o’clock

[01:00:26:16 – 01:00:27:19]

in the morning in July,

[01:00:27:19 – 01:00:47:11]

August, even in June because they have so many patrons. So the idea is you got to get out there, get the beach done quickly. The third factor is maintenance cost. Sometimes that factor is lost when people are actually making the purchase. They’re more focused on what’s the basic purchase price, but in the beach cleaning industry, it’s critical to take

[01:00:47:11 – 01:00:57:22]

account the cost of maintenance and spare parts. With any piece of equipment that’s operating in a sand, in a saltwater environment, that’s a crucial factor.

[01:00:58:22 – 01:01:01:12]

And that’s one of the, again, the reasons that we dominate the industry.

Whether you manage a municipal coastline, a resort property, or a private shoreline, your beach cleaner is a daily-use investment. Its design determines how quickly you can prepare your beach, how well it adapts to changing sand and debris conditions, and how much it costs to maintain over time.

Table of Contents

1. Adaptability to Different Beach Conditions

No two beaches are the same — and many can change dramatically from one day to the next as nature, guests, and beach uses/events change.

That’s why adaptability is often the most overlooked but most important factor when purchasing a beach cleaner.

Different machine designs perform better under different conditions:

- Walk-behind sifters work well for small, consistent beaches or dry-sand zones. They’re lightweight, simple, and ideal when you’re cleaning fine debris in smaller areas of uniform sand.

- Sifting-style towed machines clean by lifting and screening the entire sand layer. They excel at removing small debris from dry, fine sand — but struggle in wet or compacted conditions and require switching out the mesh screen to handle different debris sizes or sand textures.

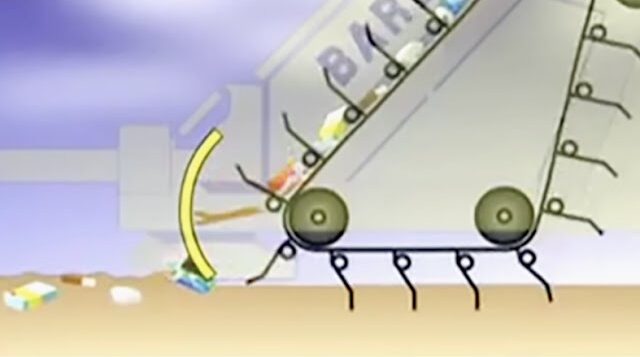

- Tine-raking beach cleaners use rows of spring tines to pick debris out of the sand surface instead of lifting the whole beach. This allows them to easily adapt between different environments — from heavy tideline sargassum one day to fine litter after a beach concert the next.

For beaches that frequently change between wet and dry zones, or that face unpredictable conditions, we’ve found an adaptable tine-raking machine offers the most flexibility with minimal setup. A few quick adjustments to cleaning depth or conveyor speed can shift it from deep wet-sand cleaning to fine surface grooming in a matter of seconds.

See how tine raking beach cleaners work to remove the debris, and not the sand.

2. Efficiency and Speed of Operation

For many operators, time is the real constraint. Most public and resort beaches must be cleaned and cleared before patrons arrive — often before 8 a.m. in peak season. That makes cleaning speed critical.

The design of the beach cleaning machine plays a huge role here:

- Sifters have to lift and process the entire layer of sand through a moving screen. It’s effective for uniform conditions but takes more time and fuel, since the machine is processing every inch of sand regardless of how clean it already is.

- Tine-raking machines operate more efficiently by picking debris out of the top layer of sand without lifting the entire beach. This reduces the mechanical load, shortens cleaning time, and allows faster ground speeds–all while still cleaning the beach just as thoroughly — which a huge advantage for municipalities, large resorts, and operators covering miles of coastline each morning.

Because tine-raking designs move less material, they also experience less wear and lower fuel consumption. That efficiency doesn’t just save time — it extends machine life and reduces maintenance costs over the long run, which leads us to:

3. Maintenance and Long-Term Cost of Ownership

Maintenance is the factor most often underestimated during the buying process — yet it has the largest long-term impact.

Any machine working in sand and saltwater needs care to remain reliable. But the level of required maintenance varies dramatically depending on the cleaner’s design:

- Sifting machines use screens and vibration systems that wear faster in salt and moisture. Screens can corrode or clog and need regular replacement, especially if you’re working in areas with wet sand or seaweed.

- Tine-raking machines use fewer moving parts and no fine screens, making them simpler to maintain. The tines and conveyor components are easy to access and made from corrosion-resistant materials, which helps reduce downtime and replacement costs.

- Regardless of design, routine rinsing after use, lubrication of key points, and storage under cover will dramatically extend the machine’s lifespan.

Over time, simpler mechanical systems tend to result in lower total cost of ownership — particularly in high-salt or heavy-debris environments. For many operators, reduced maintenance becomes the single biggest ROI factor when comparing machines.

Balancing Adaptability, Speed & Maintenance

Sifters can excel on uniform beaches where fine debris and dry sand dominate.

Walk-behinds are ideal for tight or seasonal spaces.

But for beaches that experience changing conditions, heavy use, or large surface areas, a tine-raking design offers a practical balance of adaptability, speed, and longevity.

In the long run, the best beach cleaner is the one that matches your beach’s variability, your operating schedule, and your maintenance resources — not just the one with the lowest sticker price.

Conclusion

Choosing a beach cleaner isn’t just about the machine itself — it’s about ensuring your operation runs smoothly, day after day, year after year.

A well-selected beach cleaning machine helps you keep your shoreline safe, beautiful, and guest-ready while minimizing labor and maintenance costs.

Before purchasing, take time to assess:

- The range of conditions your beach faces (wet vs. dry, debris types, usage).

- Your daily cleaning window and available manpower.

- Your tolerance for maintenance and parts replacement.

The right combination of adaptability, speed, and reliability will keep your beaches pristine – and your operations efficient – season after season.

Learn More

Need help determining which type of beach cleaner fits your conditions best?

👉 For personalized advice, contact the Barber team — we’re happy to help match you with the right equipment for your shoreline, as we’ve been doing for customers for over 60 years across over 90 countries. We’ve seen all the types of beaches out there and likely can quickly provide a recommendation that will save you days of research.

Frequently Asked Questions

Sometimes. It depends on the types of material you need to collect and how much debris is regularly on your beach. Walk-behind beach cleaners are ideal for smaller properties, coves, or narrow stretches where maneuverability matters more than cleaning speed. They’re easy to store, quick to set up, and operate on the same principles as larger machines — just scaled down for lighter, localized use. However, due to the sifting mechanism and small hopper capacity, they can be less effective for heavily-littered beaches and ineffective if seaweed or sargassum is present.

Modern tractor-towed beach cleaners are built for straightforward operation. Once connected to the tractor’s PTO and hydraulic system, setup typically takes only a few minutes. Operators can learn basic functions in a single training session, and daily cleaning requires minimal adjustment once the depth and conveyor speed are dialed in. The result is a simple, repeatable routine that produces consistently clean beaches with very little oversight.

To review the Surf Rake’s operation procedures, view our operator training video.