When you’re investing in a beach cleaner, you’re not just considering the purchase price — you’re also thinking about what it will take to keep that machine running reliably season after season…or at least, you should be.

One of the most common questions municipalities, resorts, and private beach operators have is:

“How much does it cost to maintain a beach cleaning machine?”

The short answer: it depends on how much, how you use it, and how well you maintain it.

Just like estimating the maintenance needs for a car, your annual costs depend on hours of operation, operating conditions, and how well you care for the equipment. Let’s look at the main factors and real-world benchmarks so you can ensure you can keep maintenance costs as low as possible over the course of your machine.

[00:59:59:19 – 01:00:03:01]

What are going to be the maintenance costs, the spare parts costs

[01:00:03:16 – 01:00:04:13]

in a given year.

[01:00:06:09 – 01:00:10:07]

number of hours used is really what it comes down to. So for example,

[01:00:10:07 – 01:00:18:06]

we’re standing here on the east coast of the United States, the particular beach that we are on. They will use the beach cleaner for about five months out of the year.

[01:00:18:06 – 01:00:24:04]

They will run the beach cleaner 10 hours a day, seven days a week, five months out of the year.

[01:00:24:04 – 01:00:32:15]

We have other clients maybe in a place like Florida where they will run the beach every day, but they’re only running it for about three hours.

[01:00:34:11 – 01:00:36:13]

So just like a car, if somebody said, what are

[01:00:36:13 – 01:00:45:17]

the maintenance costs going to be on a car? I would have to ask you, how many miles are you going to drive a year? Who’s driving the car and what kind of maintenance are you doing?

[01:00:45:17 – 01:01:01:07]

So not to skirt the question, I would say the average customer that is using the beach cleaner, approximately 1,500 hours a year, is probably going to incur about $3,000 in spare parts costs on the flagship model, the 600HD.

what are going to be the maintenance costs, the spare parts costs in a given year?

The number of hours used is really what it comes down to. So for example,

We’re standing here on the east coast of the United States, the particular beach that we are on. They will use the beach cleaner for about five months out of the year.

They will run the beach cleaner 10 hours a day, seven days a week, five months out of the year.

We have other clients maybe in a place like Florida where they will run the beach every day, but they’re only running it for about three hours.

So just like a car, if somebody said, what are

the maintenance costs going to be on a car? I would have to ask you, how many miles are you going to drive a year? Who’s driving the car and what kind of maintenance are you doing?

So not to skirt the question, I would say the average customer that is using the beach cleaner, approximately 1,500 hours a year, is probably going to incur about $3,000 in spare parts costs on the flagship model, the 600HD.

Table of Contents

1. What’s Included in Maintenance (and What Isn’t)

First let’s define what we mean by ‘maintenance costs.’ The phrase “maintenance costs” can mean different things. Here’s how to separate what’s routine from what’s unexpected.

A. Preventive Maintenance

These are recurring tasks designed to keep your machine in top shape:

✔ Regular greasing of bearings and pivot points

Chain lubrication and belt inspection

✔ Checking screen tension and alignment

✔ Inspecting tires and hydraulics

Cost: Mostly labor and supplies — inexpensive and quick to execute, but critical for longevity.

B. Wear Parts

These are components that gradually wear down through normal use:

✔ Pickup tines or screens

✔ Bearings, bushings, and seals

✔ Chains and belts

✔ Drive sprockets and idlers

Cost: For the Surf Rake, replacements for common wear items, like tines can begin piecemeal around year 2-3, depending on use and begin around $100 and goes up from there. Most other items should be foolproof for the first 5 or even 10 years of operation, except in cases of extremely heavy daily use.

Screens on sifting-style machines are known to require full replacement more frequently.

C. Repairs or Unexpected Damage

These costs typically arise from user error and are uncommon— like driving into structures.

Our Surf Rake is actually designed to minimize these kinds of damage. For example, the moldboard deflector plate at the front of the machine helps it pass over large submerged objects without harming the conveyor system. Most sifting-style units, however, can bend or break the cutting edge when encountering unexpected submerged objects.

Cost: Depends on the type of damage. Most Surf Rake repairs can be done with simple mechanical tools. Other beach cleaners’ replacement parts & processes vary.

2. The Factors That Affect Beach Cleaner Maintenance & Repair Costs & time

Every beach has its own rhythm and maintenance needs. These patterns have a big impact on annual maintenance budgets.

A. Operating Hours

Usage hours are the single biggest cost driver. For example:

✔ Seasonal operation (northern U.S.) — about 10 hours per day, 7 days a week, for 5 months → roughly 1,500 hours per year

✔ Year-round light use (southern climates) — around 3 hours per day, 7 days a week, all year → about 1,000 hours per year

While the recommended preventative maintenance will be the same frequency/intervals with both machines (during periods of use), the repairs costs on the year-round machine with lighter use will actually be less than the heavy-use seasonal machine, even though it runs more frequently throughout the year.

The more hours the machine runs, the more frequently screens, bearings, and drive components will need adjustment or eventual replacement.

B. Beach Conditions

Sand texture and debris load vary dramatically from beach to beach and also influence the frequency and cost of the maintenance of wear parts:

✔ Fine, clean sand is gentle on the machine and screens, so you’ll likely require fewer replaced parts over time than the average.

✔ Coarse sand, shells, or coral fragments increase wear on moving parts.

✔ Debris-heavy beaches (sargassum, seaweed, sticks, or litter) can accelerate wear on pickup systems and belts.

C. Operator Habits

Just like driving style affects a car’s lifespan, operator operation styles and maintenance care are one of the biggest determinants of overall maintenance & repair costs.

If the operator operates the machine as deep and fast as it can go all the time, regardless of beach conditions, it will wear much faster. Meanwhile, an operator who adjusts cleaning styles to match the conditions of the beach and only digs deeply when needed will reduce costs over time.

D. Consistency of Routine Maintenance

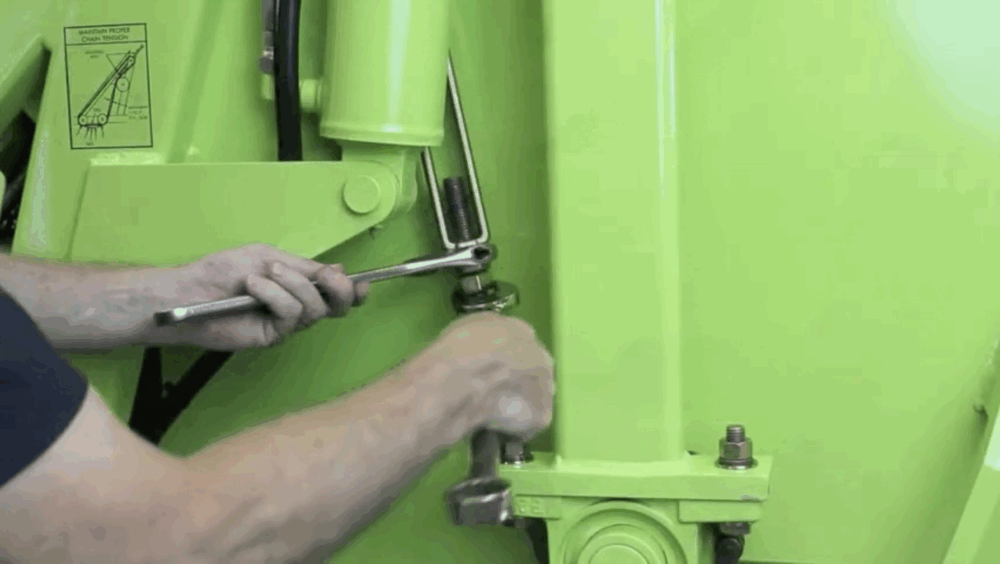

Similarly, routine greasing, correct chain tensions, and timely part inspections can easily double the life of key wear components.

For example, we recommend operators grease the Surf Rake’s bearings every two weeks of regular use and check the chain tensions to make sure they have not loosened and introduced extra vibration & friction into the unit.

Simply doing these two things dramatically extends the life of the wear parts of the machine

E. Storage and Environmental Exposure

Salt air, humidity, and sun exposure can cause corrosion and deterioration over time. Proper off-season storage — ideally indoors and out of the elements — helps prevent these issues and lowers long-term costs.

While some of the factors that affect beach cleaner maintenance and repair costs over time are out of your control–like the operating hours and beach conditions– being consistent with preventative maintenance care and operating your beach cleaner within recommended guidelines can dramatically reduce maintenance costs over time.

Let’s see how these broad principles can be applied to a specific machine:

3. Reducing maintenance costs & extending machine life:

EXAMPLE: THE SURF RAKE 600HD maintenance recommendations

Now let’s look at some specific maintenance recommendations and repair frequencies to drive home the principles by reviewing the maintenance recommendations for Barber’s Surf Rake 600HD.

Every 1-2 Weeks

Preventative Maintenance:

✔ Grease the bearings & moving parts (~5 minutes)

✔ Check/Tighten Conveyor & Dump Chains for proper tension (~1-15 min, depending on if tightening is required–typically only needed every couple months)

Every 2 months

✔ Inspect and tighten drive chain, if needed– 1 minute (typically only needs tightening once/season-~10 minutes)

ONce/Season

At the close of the operating season (or once annually for year-round operations):

✔ Inspect conveyor assembly and bearings for looseness or worn parts.

✔ Replace any worn tines, bearings, chains, or seals, as needed.

4. Another less-thought-of way to save money on beach cleaner maintenance

One of the biggest ways to reduce long-term maintenance costs that is often overlooked prior to purchase is to choose a beach cleaner that is designed to require less maintenance over time.

A simple, robust mechanical beach cleaner — such as the Surf Rake typically costs less to maintain than units loaded with electronics or vibration systems.

Here’s why:

A. Fewer Moving or complex parts = Fewer Failures

Fully-mechanical systems avoid the complexity of sensors, processors, and electronic controls that can corrode or short-circuit in salty environments.

B. Easy, On-Site Serviceability

Most mechanical systems can be maintained with standard tools, reducing downtime and dependency on specialized technicians.

C. Durability and Proven Parts

Galvanized steel, hardened bearings, and robust conveyor designs translate into longer component life — even under heavy use.

By contrast, beach cleaners that rely on vibration systems, screens, or electronic controls often require more frequent part replacements and diagnostic service, increasing both downtime and cost.

We explore how to identify a beach cleaner that will likely incur fewer maintenance costs over time in more detail in our article: Design Principles for Long-Lasting Beach Cleaning Machines.

5. How Long Do Beach Cleaners Last?

Ultimately, with proper care, a well-built beach cleaner, like the Surf Rake, can operate consistently for 15 years or more.

Many municipalities still use machines purchased decades ago that continue to perform reliably with basic annual servicing.

6. predicting beach cleaner maintenance costs for your beach.

While all these principles and examples can be helpful, you likely want to know how much you’ll need to budget for maintenance & repair costs for a beach cleaner, if you purchased & used one on your beach.

Since this prediction requires taking many variables into account, like those we’ve mentioned (use frequency, your beach & debris type, specific machine) we can’t give you exact numbers in a blog post.

However, our current sales team has helped thousands of customers and have a combined experience of over 100 years working with beach cleaning customers like you.

So if you’d like to discuss potential maintenance and repair costs for your beach, we recommend you contact our team by using our contact form or calling our headquarters directly (+1 203-729-9000), and we can provide you with a more specific estimate.

Next Steps

✔ Contact our Team for a Maintenance Cost Estimate: Contact Us

✔ Learn more about Barber’s maintenance and repair practices : Surf Rake Customer Service Portal

frequently asked questions:

Not necessarily. In most cases, a well-built mechanical beach cleaner costs less to maintain than similar-sized tractors, mowers, or golf course equipment. That’s because there are no electronics, drive trains, engines, or complex diagnostics to service. Most repairs can be performed with standard tools by local maintenance staff rather than specialty technicians.

While we can’t speak for other beach cleaner manufacturers, most regular service procedures for the Surf Rake —like greasing, chain adjustments, tine replacement, etc. — can be handled on-site by your existing maintenance team. Barber machines are intentionally designed with easily accessible fittings and standard hardware to minimize downtime. Only rare structural repairs or complete overhauls require factory assistance.

Saltwater accelerates corrosion on unprotected steel and electrical components. Choosing a cleaner with galvanized frame and stainless-steel components and that is a sealed mechanical system greatly reduces this risk. The Surf Rake uses mostly stainless steel components that hold up to many years in sand and salt-water environments.

Barber maintains a stocked parts inventory at its factory for same-day shipping, and we have a world-wide network of dealers, who also store the most common replacement parts. This means even mid-season part swaps typically cause minimal downtime.

In most cases, the parts won’t completely fail– the machine will just become less effective over time, or the worn part will cause other healthy parts to wear faster. Regular inspections of tines and chain components will identify acute breakages, as well as parts that are getting close to failure or introducing too much slack/vibration into the system.

Yes. Especially in the case of substantial sargassum cleanup, heavy debris can increase the load placed on the conveyor system and the frequency of dump cycles, leading to faster-than-average wear. Adjusting cleaning depth and slowing ground speed in these conditions can offset some of that wear, keeping costs predictable even on challenging beaches.