rock pickers: turf rake

Small Rock Picking machine

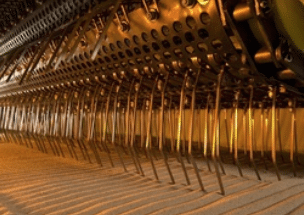

The TURF RAKE is a rock picker designed to remove small rocks (1/2 – 4″ in diameter) that larger rock pickers leave behind.

There are three models of TURF RAKE rock pickers available. The most popular and widely used model is the Model 600HD. The 600HD cleans a seven-foot swath. The Model 600HD has a three cubic yard capacity hopper, which can be raised to a height of nine feet for dumping into any size dump truck.

The medium size Model 400HD rock picker has a six-foot cleaning width and a two cubic yard capacity hopper, which can be elevated nine feet for discharge.

The Model 400 rock picker has a 6-foot cleaning width. The hopper on the Model 400 is 1 cubic yard and deposits the debris on the ground at the rear of the unit.

Learn more by visiting the links below!