SURF RAKe service

HOW TO ADJUST THE MOLDBOARD

REQUIRED TOOLS

Adjustable wrench

QUESTIONS?

Contact a Barber team member at:

(800) 355-8318 or hbarber@hbarber.com

what does the moldboard do?

The moldboard is the rounded shield in the front of the SURF RAKE. It serves several functions:

1. Deflects debris onto the conveyor belt to be removed from the sand:

Since the tines are combing through the sand very quickly, they fling newly removed debris forward in the motion they are going. The curve on the inside of the moldboard deflects the debris back onto the conveyor (as shown by the cup in the diagram above), and the tines carry the newly separated debris up to the hopper.

2. Levels the cleaning area

A moldboard’s natural curve simultaneously levels the beach while riding over larger, immovable objects. Instead of hitting a submerged object straight on, like an ax hitting a log, the moldboard’s curve lifts the beach cleaner over the submerged object, while the spring-action tines simply flex over the object without being damaged.

Another great benefit of leveling the beach is that it creates an even plain of sand for the tines to then rake. This ensures that every part of the beach is cleaned thoroughly and evenly with equal tine penetration.

3. Controlling cleaning depth

Once the sand is leveled, the tines can clean the entire width of the machine to an even depth. Adjusting its height controls how deeply the tines penetrate the sand. When the moldboard is raised and the turnbuckles or cylinders are lengthened, more of the tines are exposed, and they will clean deeper into the sand. When the moldboard is lowered and the cylinders or turnbuckles are shortened, the tines will not dig as deeply into the sand.

4. Protecting the conveyor system.

By shielding the tines and conveyor belt from constant abrasion, the impact of the sand, and potentially harmful submerged objects, the moldboard protects the conveyor belt from many of the main damaging elements that most beach cleaners’ cleaning mechanisms are exposed to. Most sifting screens need to be replaced every year and tightened periodically, because they are the first component to hit the sand while spinning around the cutting edge. This proves annoying and expensive. The conveyor belts and tines on beach cleaners that utilize moldboards, however, tend to last many years.

HOW TO ADJUST THE MOLDBOARD

#1 There are two ways to adjust your Moldboard’s height, depending on your Surf Rake configuration.

#2 Manual configuration – by tightening and loosening the turnbuckles.

#3 Hydraulic configuration – from the cab of the tractor.

MANUAL CONFIGURATION

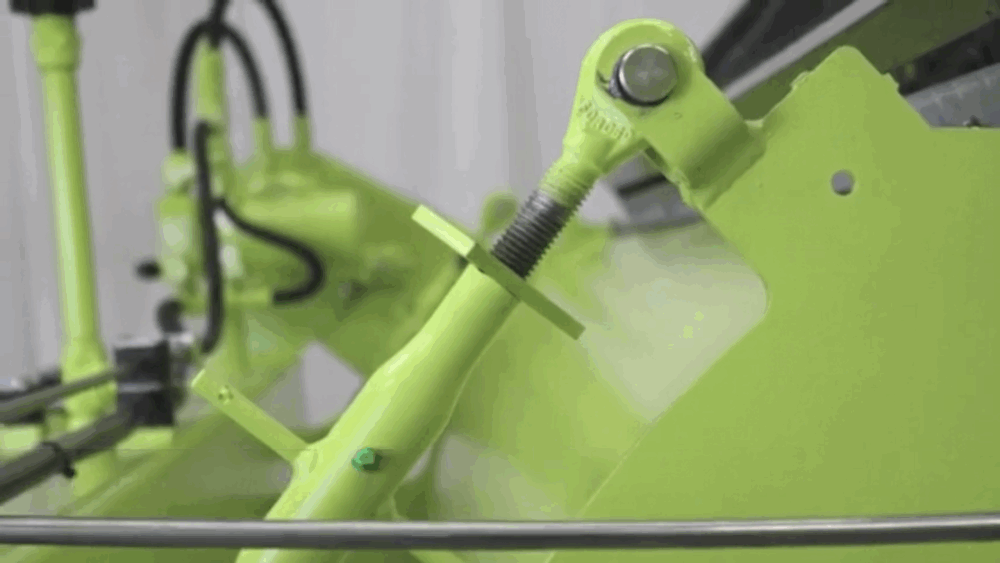

#1 Use an adjustable wrench and then your hands to loosen the locking plate on the turnbuckle.

#2 To lower the Moldboard, tighten the turnbuckle by hand so that fewer threads are visible.

#3 Repeat the process on the other side, ensuring that both sides are set equally.

#4 When the desired height is reached, secure the locking plate to lock the Moldboard in position.

#5 To raise the Moldboard, repeat the same process, but this time loosen the turnbuckle so that more threads are visible.

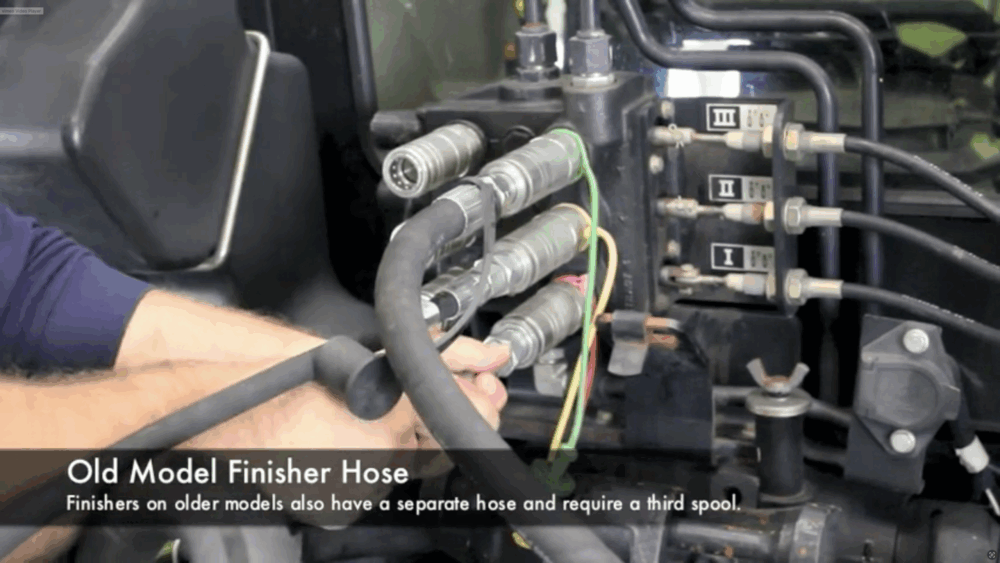

#12 Older model finisher hose – finishers on older models also have a separate hose and require a third spool.

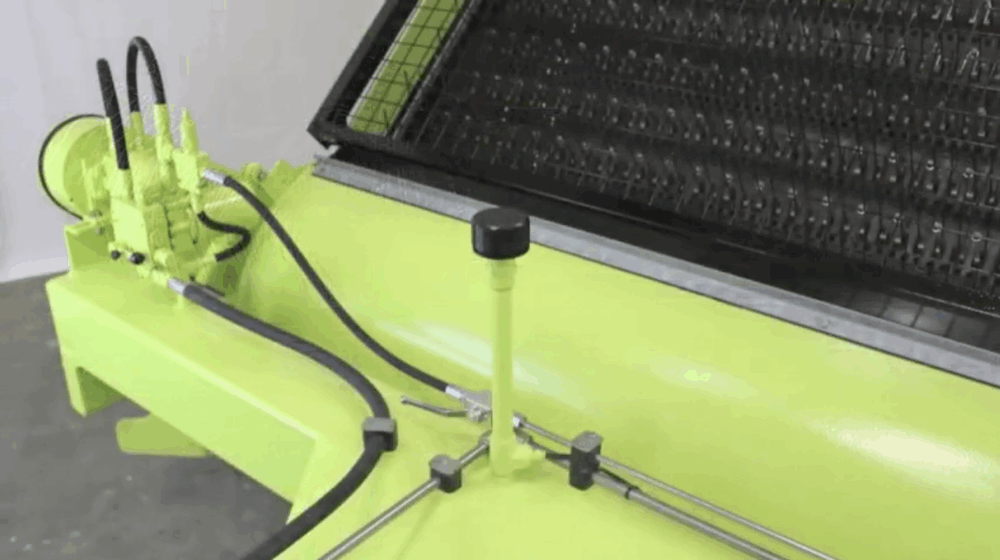

HYDRAULIC CONFIGURATION

#1 Make sure the hoses are secure next to each other- one on the send and one on the receive line.

#2 Control the Moldboard height using the lever in the tractor.

#3 Number 6 on the cylinder means the Moldboard is at its highest and the deepest clean.