SURF RAKe service

REPLACING A STUD

REQUIRED TOOLS

Hammer

Cylinder Safety Support

Oil-Based Lubricant

5/8″ socket

Stud puller

Nickel Anti-Seize

1/2″ Socket

FREQUENCY

Only if stud is damaged

REPLACING A STUD

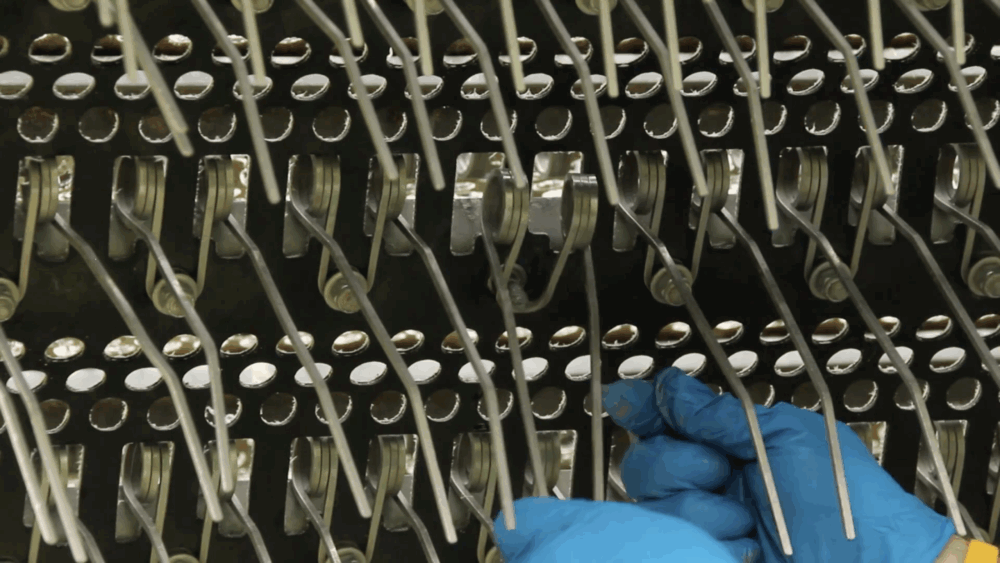

#1. Locate the damaged stud.

#2 Rotate the Conveyor to bring the stud to the top.

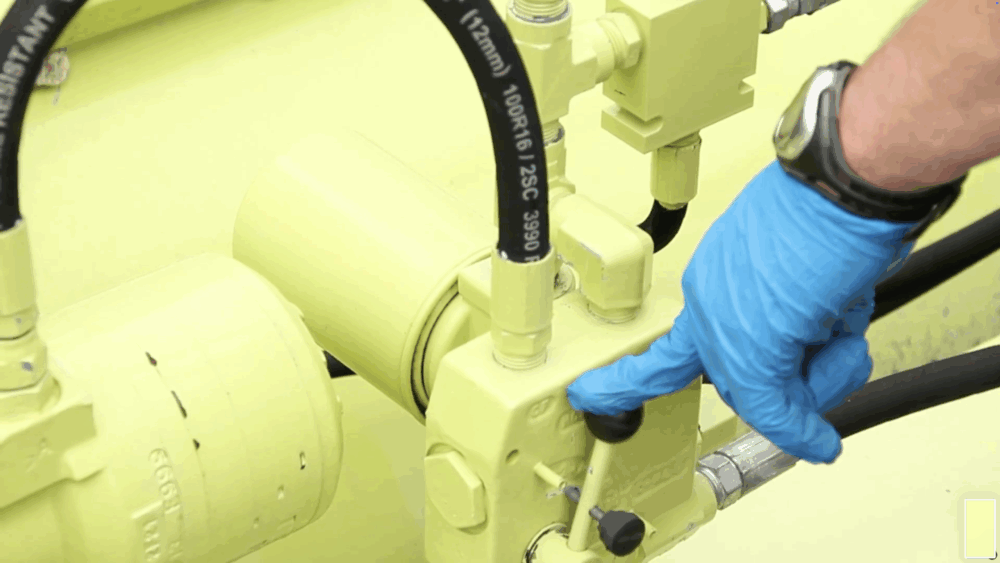

#3 Insert bucket safety stop.

#4 Remove damaged stud.

#5 Rotate Conveyor until the stud is in the middle of the conveyor, so it can be accessed from the side door..

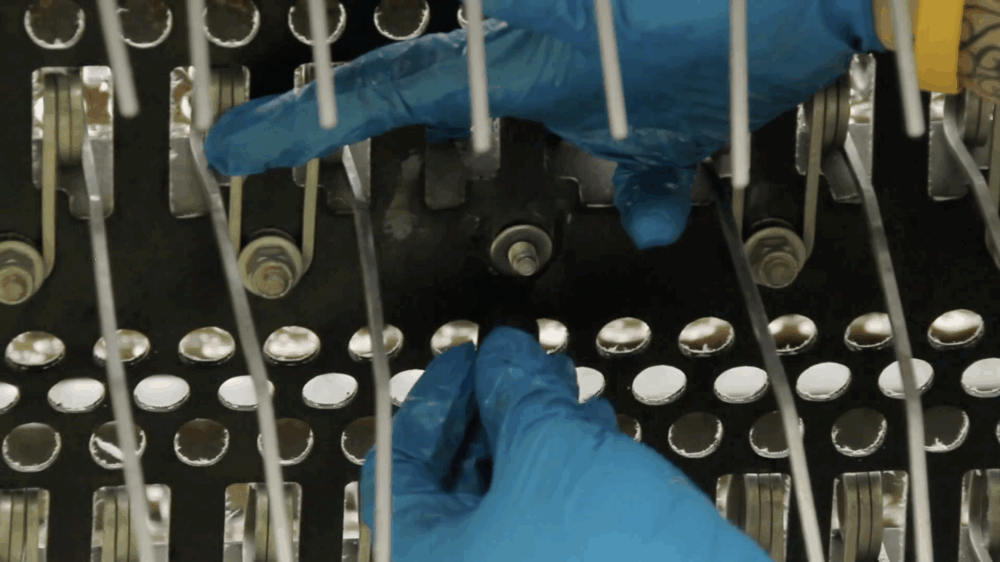

#6 Open the conveyor side door, and insert the new stud.

#7 Lubricate the stud and stud puller.

#8 Attach the stud puller to the stud.

#9 Pull the stud through the channel.

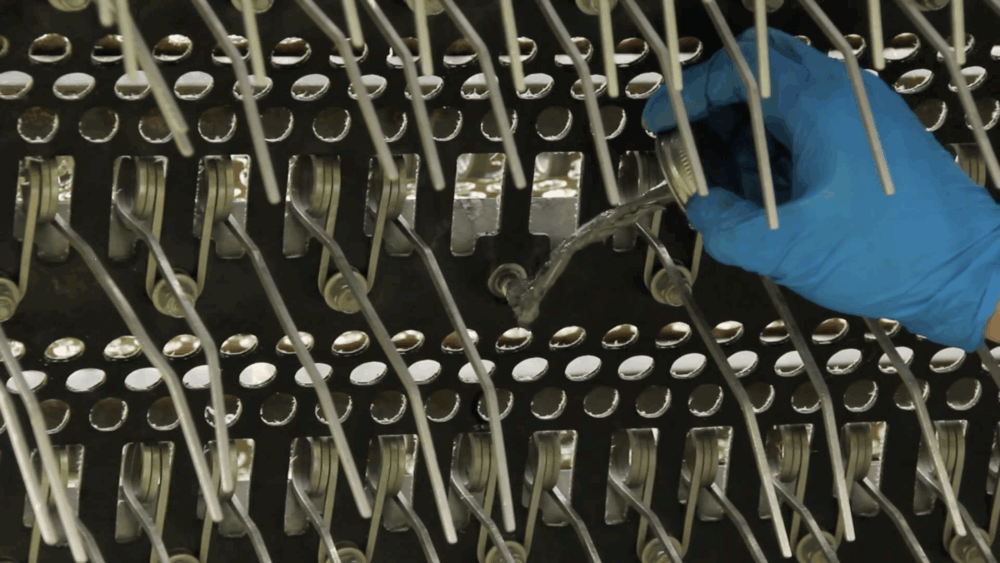

#10 Detach the stud puller.

#11 Apply nickel anti-seize.