SURF RAKe service

GREASING THE SURF RAKE

The SURF RAKE requires minimal greasing to ensure long machine life. However, a regular greasing schedule fortifies the primary conveyor bearing against wear over time.

REQUIRED TOOLS

Grease Gun

Standard Machine Grease (NLGI #2 recommended)

FREQUENCY

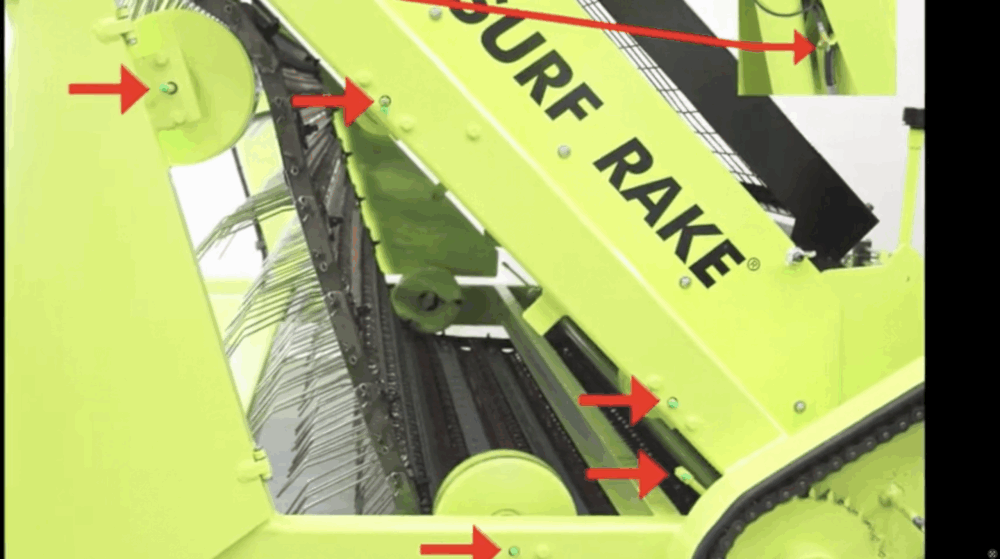

Once/Week for Conveyor Bearings

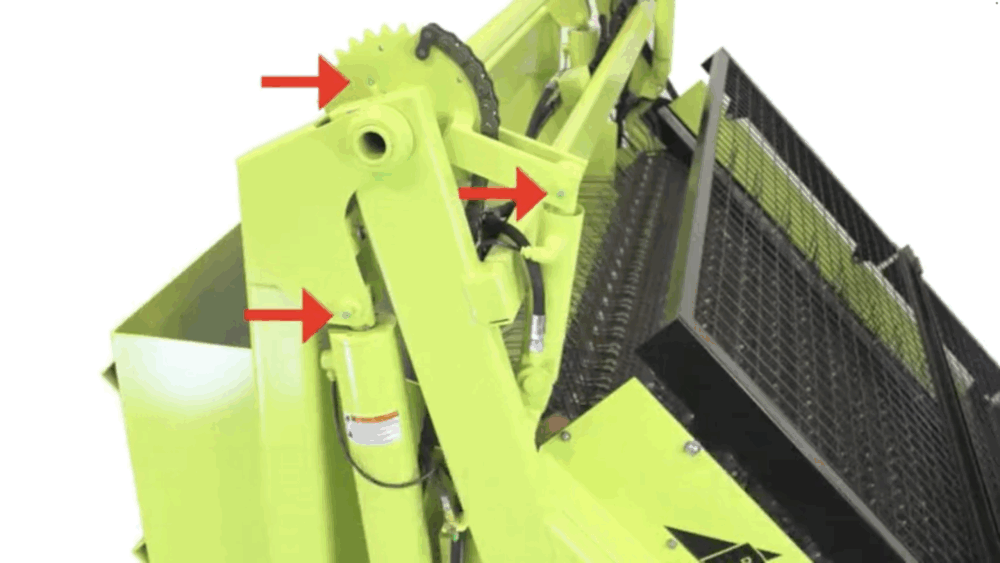

Once/Month for other pivot points

QUESTIONS?

Contact a Barber team member at:

(800) 355-8318 or

hbarber@hbarber.com

GREASING THE SURF RAKE

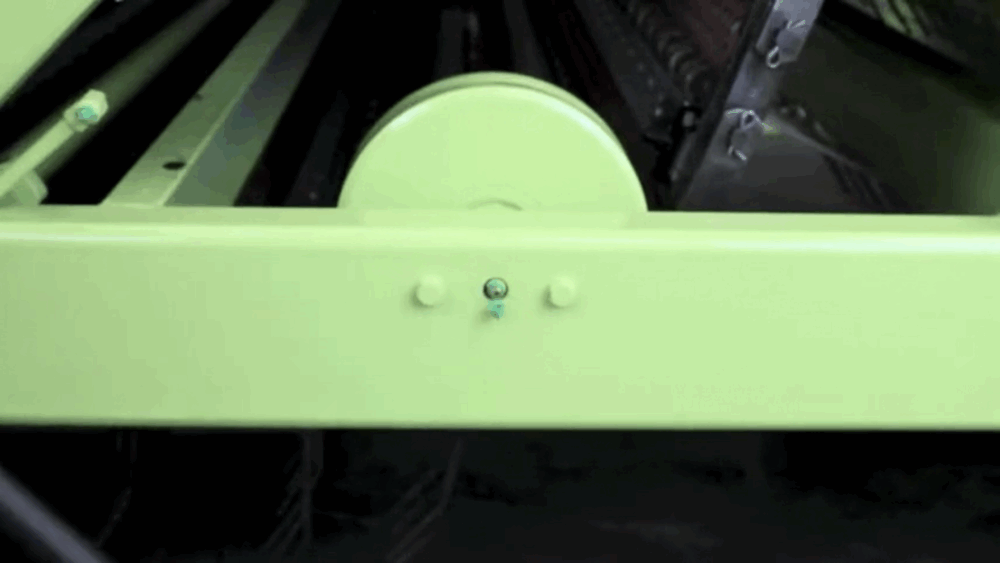

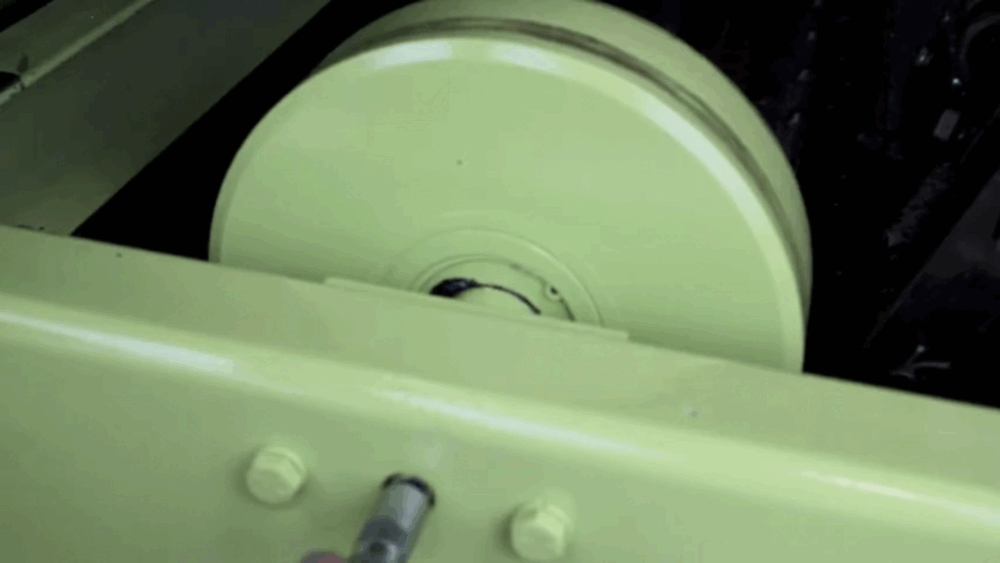

#1 Uncover the nipple of the grease fitting.

#2 Fit the grease gun’s nozzle onto the nipple.

#3 Squeeze the grease into the bearing until a small amount of grease escapes.

#4 Grease the five major conveyor bearings and idlers on each side of the Surf Rake every week during regular use.