litter picker lp1:

Windblown litter removal for landfills

A tractor-towed, purpose-built solution for clearing plastic film, foam, paper, and mixed debris from slopes, soil, and perimeter areas.

If you’re responsible for keeping your landfill clean and compliant, you already know that windblown litter doesn’t stay where it lands. Plastic film, foam, and loose packaging spread quickly across grassy slopes, berms, and wide soil areas—especially after windy days. Manual crews work hard, but the scale, spread, and inconsistency of litter makes hand retrieval slow and unpredictable.

That’s why many landfill teams turn to the Barber Litter Picker (LP1)—a tractor-towed, mechanical cleanup tool designed specifically for the terrain and debris types found at landfills across the country. It provides consistent daily pickup, reduces the most repetitive cleanup tasks, and helps your team stay ahead of whatever the weather brings.

Case Study: southern oklahoma regional disposal

See the Litter Picker in Real Landfill Conditions

Battling persistent Oklahoma winds, the Southern Oklahoma Regional Disposal landfill used the Barber Litter Picker to catch up with its windblown litter problem, so they could stay compliant, despite having limited access to manual labor. Learn about how the Litter Picker fit into their operation to dramatically simplify their litter control efforts.

key benefits for landfill operations

Fast Cleanup Speeds

Free up time for other projects by reducing cleanup time.

Consistent Daily Results

Reliably scales to handle unpredictable volumes and spread.

Ensure Compliance

Avoid write-ups & penalties & improve community relations

Suports Manual Crews

Handle much of your team's time-consuming, repetitive cleanup tasks.

Why the Litter Picker works for Windblown Litter at Landfills

1. Designed for Diverse Terrains

The LP1 performs on soil, grass, packed surfaces, pavements, berms, and slopes without digging or scalping. Its moldboard and tine system “rides” the ground smoothly and keeps debris flowing cleanly onto the conveyor—even on uneven surfaces. It also has a low center of gravity that keeps it stable when operating on steeper-than-average slopes.

2. Picks Varied Litter Types

From paper & shredded foam to loose bags and small wood fragments, the LP1 handles the types of mixed litter that manual crews struggle with. It collects material cleanly while minimizing soil disturbance.

3. Fast, Repeatable Daily Cleanup

Crews don’t need to chase litter across large areas. The operator simply drives the tractor and clears each section in a single pass—making cleanup more consistent, especially on windy days.

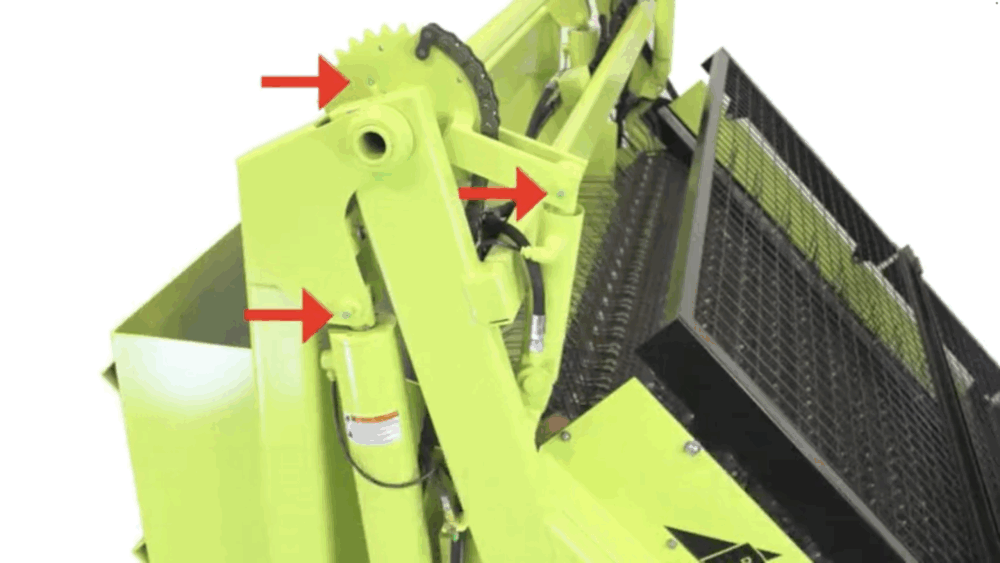

4. Simple Operation + Easy Maintenance

No constant adjustments. No complicated electronics.

No special operator license required. Most maintenance is basic greasing, with all points easily accessible.

see if the litter picker is a good fit for your landfill

faq: Litter Picker for Landfill Use

Below are common questions landfill operators ask when evaluating litter control equipment for their site.

Yes. The Litter Picker is designed to operate on typical landfill slopes, grassy areas, and uneven terrain. It’s commonly used on side slopes, perimeter areas, and flat zones near haul roads and the top of the landfill.

The Litter Picker is effective at collecting common windblown landfill debris, including plastic bags, film, Styrofoam, cardboard, paper, and other lightweight materials that escape the active face or fall from trucks.

The unit is tractor-mounted and operated hydraulically from the cab of the tractor. Operators simply turn on the PTO shaft, lower the machine onto the ground, and drive forward while the picker collects litter into the hopper. Training is minimal, and most crews are productive right away. If your operator can drive a tractor, they can easily operate the Litter Picker.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Dumping is quick and straightforward. The 4-cubic-yard hopper allows operators to collect a large volume of litter before dumping, reducing trips back to the active area and keeping cleanup efficient. The actual dump cycle takes around 30 seconds.

Yes. Many landfills use the Litter Picker specifically along perimeter fencing, access roads, and boundary areas to intercept litter before it leaves the property.

Landfill maintenance teams use the LP1 in different ways, based on their priorities. It can be a great benefit for under-staffed landfills where finding regular labor is challenging, because it can clean significantly more area than a small team in a day. That being said, other landfills prefer to keep their laborers on the team and use the added efficiencies of the machine to free them up to work on other projects to better the landfill. We’ve found having both laborers and the LP1 can open up even greater efficiencies, as the labor teams can centralize litter, while the LP1 can quickly pick it up and transport it to the disposal site, without needing to waste time on garbage bags, bins, and carrying debris to and from the dump site manually.

We recommend speaking with our team, so we can provide recommendations for how to integrate the LP1 into your operations to generate the greatest efficiencies.

Absolutely. Rentals are a common starting point. They allow your team to evaluate performance on your specific terrain, litter conditions, and workflow before deciding whether to continue renting or purchase. In many cases, the rental fees can be contributed towards to purchase of a machine.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

The Litter Picker is compatible with a range of tractor sizes commonly used at landfills. Typically, we recommend a 50 to 60 HP rubber-tired tractor with 540 PTO, 3-point hitch and two auxiliary hydraulic outlets.

Delivery timelines vary by location and if we have units currently in stock, but rentals are typically arranged quickly, as all our operations are in one location at our factory in Connecticut. Contacting us early allows us to confirm availability and logistics for your site.

Routine maintenance is minimal and consists mainly of standard inspections and basic upkeep. We recommend greasing several easy-to-access grease points every couple weeks. Other than that, the only other real up-keep we’ve found landfill teams need to do on occasion is to pick plastic bags off the tines, which only takes a couple minutes after a cleaning is complete, if needed at all.

Yes. Our team is available to answer questions, provide operational guidance, and help ensure you’re getting the most out of the rental during your evaluation period.